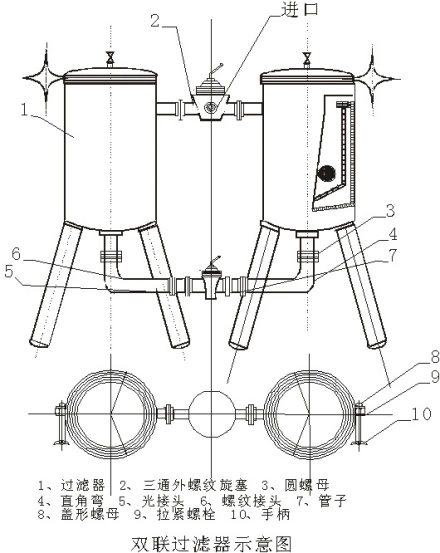

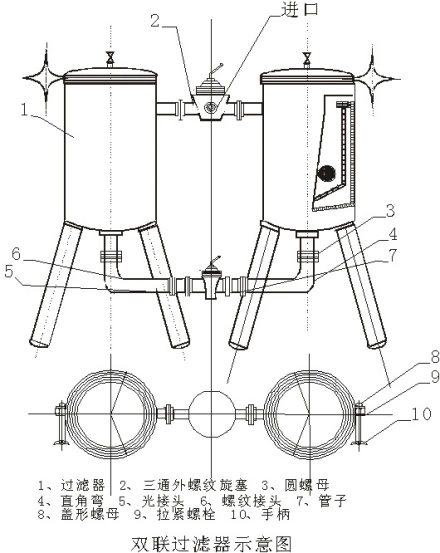

The equipment is used for filtering liquid materials. The continuous working filter screen is convenient for replacement

Duplex filter is also called duplex switching filter. It is a multi-purpose filtering equipment composed of two stainless steel filters in parallel. It has many advantages, such as novel and reasonable structure, good sealing, strong flow capacity, simple operation, etc., and has a wide range of applications and strong adaptability. In particular, the side leakage rate of the filter bag is small, which can accurately ensure the filtering accuracy, and can quickly replace the filter bag. There is basically no material consumption for filtering, which reduces the operating cost.

working principle

The equipment is made of stainless steel, which is composed of two columns. It is a single-layer stainless steel welded structure. The internal and external surfaces are polished. The top is equipped with an air release valve for air release during operation. The pipe joint is connected by expansion. After 0.3Mpa water pressure test, the three-way external thread cock can be opened and closed flexibly. The equipment is compact in structure, convenient in operation and simple in maintenance.

The duplex filter, also known as the parallel switching filter, uses two three-way ball valves to assemble two single cylinder filters on a base. When cleaning the filter, it does not need to stop to ensure its continuous operation. It is the first choice for the filter device of the non-stop production line. In addition to the stainless steel filter element, the filter element of this filter can also be made of high-quality honeycomb type degreasing fiber cotton, which can filter out particles with a size of 1 μ For the above particles, the filter can also be used in a single cylinder. At this time, only the common base needs to be removed, and the other dimensions remain unchanged.

The inner and outer surfaces of the duplex filter are polished, and the filter cartridge is equipped with a stainless steel filter screen and a filter screen support basket; A vent valve is installed on the top to discharge the air in the filter during filtering. The quick opening structure is adopted for the connection between the upper cover and the filter cartridge, which is more convenient for cleaning (replacing) the filter screen. Three adjustable feet can make the filter stably placed on the ground. The connecting pipeline is connected by union or clamp, and the inlet and outlet valves are opened and closed by three-way ball valves, which are resistant to pressure and temperature, flexible and convenient to operate, and more sanitary without material leakage.